Aggregate for highway project is widely applied in building road, tunnel, bridge and culvert, etc, the application of aggregate with the most consumption and high technical requirements is road pavement.

It can be used for various hard materials such as granite, basalt, diabase, etc.

It is suitable for application in highway, urban construction and airport construction, etc.

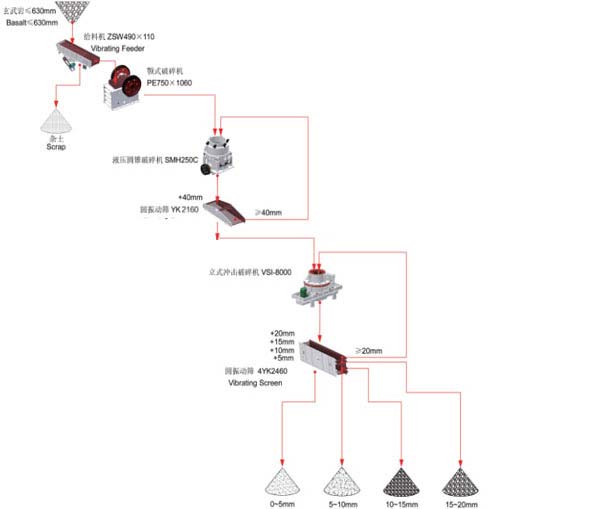

Jaw crusher, hydraulic cone crusher, VSI sand making machine, vibrating feeder, vibrating screen.

Highway construction imposes strict requirements on particle size and sand grading of aggregate, especially for needle flake content of crushed stone. In order to solve the requirements of consistency, cleanness and particle content with size of 0.075mm with respect to particle size and grading, particle shape and particle composition, Sanme puts the new type of sand making machine in the production line to satisfy the requirements of aggregate for highway cement and asphalt.

Rock will be conveyed by vibrating feeder to jaw crusher for primary crushing, secondary crushing will be fulfilled by cone crusher, the material from cone crusher will be conveyed to vibrating screen for screening, material with size larger than 40mm will be conveyed back to cone crusher for crushing again to achieve a closed circuit, material with size less than 40mm will be conveyed to vertical shaft impact crusher for crushing and shaping. Material from vertical shaft impact crusher will be conveyed to final product screen for screening, material with size larger than 20mm will be conveyed back to impact crusher for recycled crushing, material with size less than 20mm will be conveyed by belt conveyor to final product pile.

Stone production line has the features of high automation, high production efficiency, low operation cost, high output, and high yield; particle size of discharging material can be adjusted, crushing rate is high, and energy saving can be achieved; product grain is uniform with excellent shape, meeting the national standard of aggregate for highway.